Cylindrical-Ib pob zeb diamond sib tsoo taub hau-txiav cov cuab yeej

Khoom duab

Product Basic Details

Khoom npe: Pob zeb diamond sib tsoo taub hau

Cov Qauv Khoom: Cylindrical-A

Lub taub hau khoom: Pob zeb diamond

Khoom siv: 1. Cov pwm yog hauv av thiab polished.2 Deburring thiab trimming ntawm stainless hlau.3 Tuag qhov kho cov txheej txheem.4 Slotting thiab sib tsoo ntawm steel qhov chaw.

Lub taub hau taub: 6mm / 8mm / 10mm / 13mm / 15mm / 18mm / 20mm

Lub taub hau Length: 30mm

Shank Length: 30mm

Qhov zoo: 1. Cov khoom siv pob zeb diamond, tsis yooj yim rau deform.2. Tsawg plua plav, tiv thaiv ib puag ncig ntau dua.3. High manganese hlau, thickened matrix.4. Lub pas nrig reinforcing yog tsim los ua kom lub neej ua haujlwm ntev.

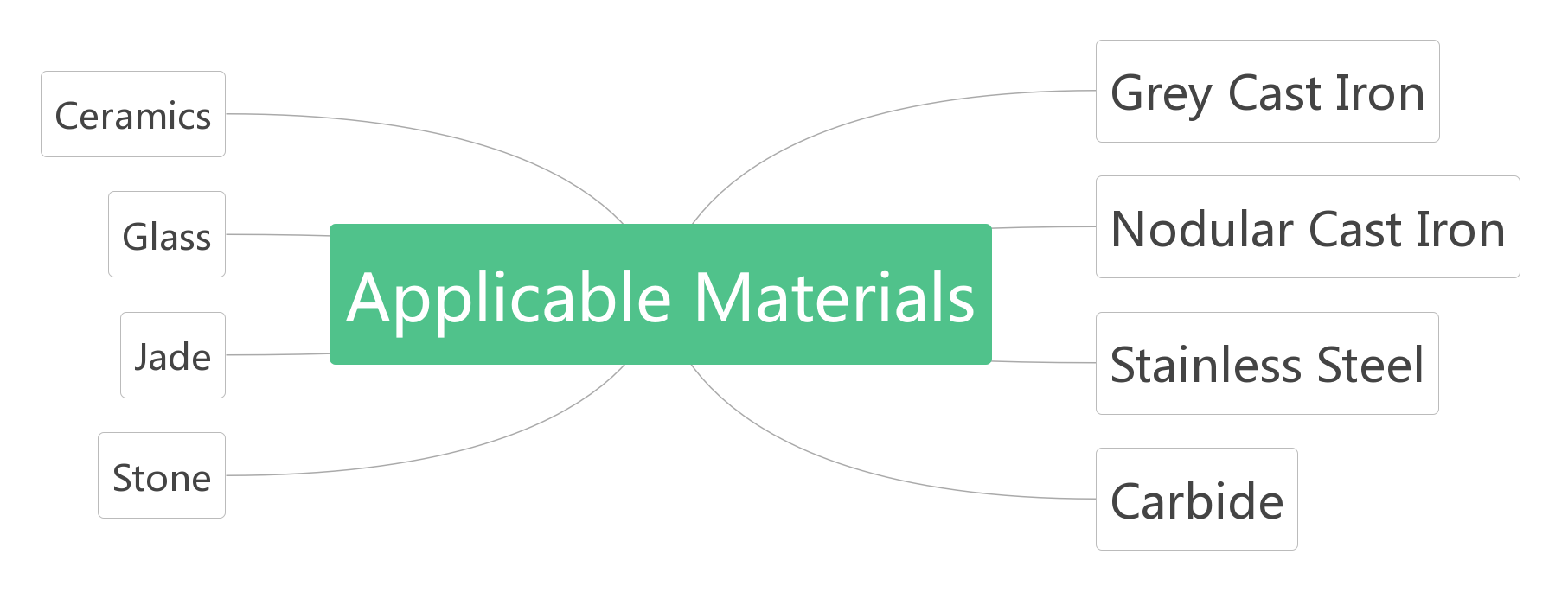

Cov ntaub ntawv siv tau

Daim ntawv thov

1. Kev ua thiab kho cov pwm.

2. Pob zeb engraving, engraving, txiav kab, sib tsoo, hollowing.

3. iav carving.

4. Kev ntxuav ntawm casting, forging, vuam npoo, burrs, welds.

5. Kev sib tsoo cov hniav.

6. Chamfering thiab groove ua ntawm ntau yam khoom siv kho tshuab, ntxuav cov kav dej, ua tiav lub qhov hauv qhov chaw ntawm cov khoom siv tshuab.

7. Kev hloov kho ntawm workpiece geometry.

8. Kho hniav engraving.

Khoom Dimensions

| Qauv | Txoj kab uas hla | Tag Nrho Ntev | Ua Haujlwm Ntev | Shank Ntev | Shank Txoj kab uas hla |

| Cylindrical 6 * 6 | 6mm ib | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 8 | 8mm ib | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 10 | 10 hli | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 13 | 13 hli | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 15 | 15 hli | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 18 | 18 hli | 60 hli | 30 hli | 30 hli | 6mm ib |

| Cylindrical 6 * 20 | 20 hli | 60 hli | 30 hli | 30 hli | 6mm ib |

Siv tau Scenario

Cov khoom sib piv

Brazing sib tsoo taub hau

● Lub neej ua haujlwm ntev, ruaj khov dua li lub taub hau sib tsoo zoo tib yam

● Cov plua plav tsawg dua, ntau tus phooj ywg ib puag ncig

● Sib tsoo ntse thiab ua haujlwm siab

● High manganese steel, thickened matrix

Cov tsoos tsoo taub hau

● Lub neej ua haujlwm luv luv, kev ntxhov siab tsis sib xws yuav ua rau deformation

● Cov plua plav yog qhov loj, ua rau muaj kev puas tsuaj rau tib neeg lub cev

● Lub neej ua haujlwm luv luv, kev hloov ntawm phau ntawv yog siv sijhawm thiab siv zog heev

● Cov khoom siv yooj yim tuav, yooj yim tawg, tsis zoo tshuav

RuiXin Qhov Zoo

1. Peb yog cov kws tshaj lij carbide burr chaw tsim tshuaj paus txij li xyoo 1992. Nrog 30 xyoo ntawm kev txiav ntug masters, thiab lub sij hawm sib tsoo ntawm workpieces yog twv yuav raug hu ntev dua li ntawm lwm tus.

2. Peb cov khoom yog 100% dimond.

3. Qee lub Hoobkas siv cov khoom siv rov ua dua tshiab los ua cov khoom lag luam pheej yig dua.

4. Qee qhov chaws tsis tu ncua muaj Tshuag thiab tuaj yeem xa tawm tsis pub dhau 7 hnub!

Pob zeb diamond sib tsoo taub hau zoo

1. Kev ua haujlwm zoo: kev ua haujlwm ua haujlwm tau nce 35%.Rau cov ntaub ntawv hardness siab thiab xuab zeb suav nrog castings, kev ua haujlwm tau nce los ntawm 5-10 lub sijhawm.

2. Cov txiaj ntsig: rau cov khoom siv hardness siab thiab cov xuab zeb suav nrog cov xuab zeb, ib daim yog sib npaug rau 100-300 cov khoom sib tsoo zoo tib yam.

3. Kev tiv thaiv ib puag ncig: lub abrasive tsis muaj leej faj, tsis poob tawm, thiab cov plua plav thiab cov pa paug paug yuav luag xoom.

4. Kev nyab xeeb: siab zog steel matrix yog saws, thiab tsis muaj peev xwm muaj kev nyab xeeb los ntawm cov khib nyiab ya tawm.