Ntoo chiselsyog cov cuab yeej siv rau kev txiav, carving, los yog khawb ntawm ntoo.Kev xaiv cov khoom tsim nyog thiab kev siv txuj ci tuaj yeem txhim kho kev ua tau zoo thiab kev ua neej nyob ntawm ntoo chisels.Nov yog qee cov lus qhia rau kev xaiv cov khoom siv ntoo chisel thiab kev txawj siv:

Kev xaiv khoom siv:

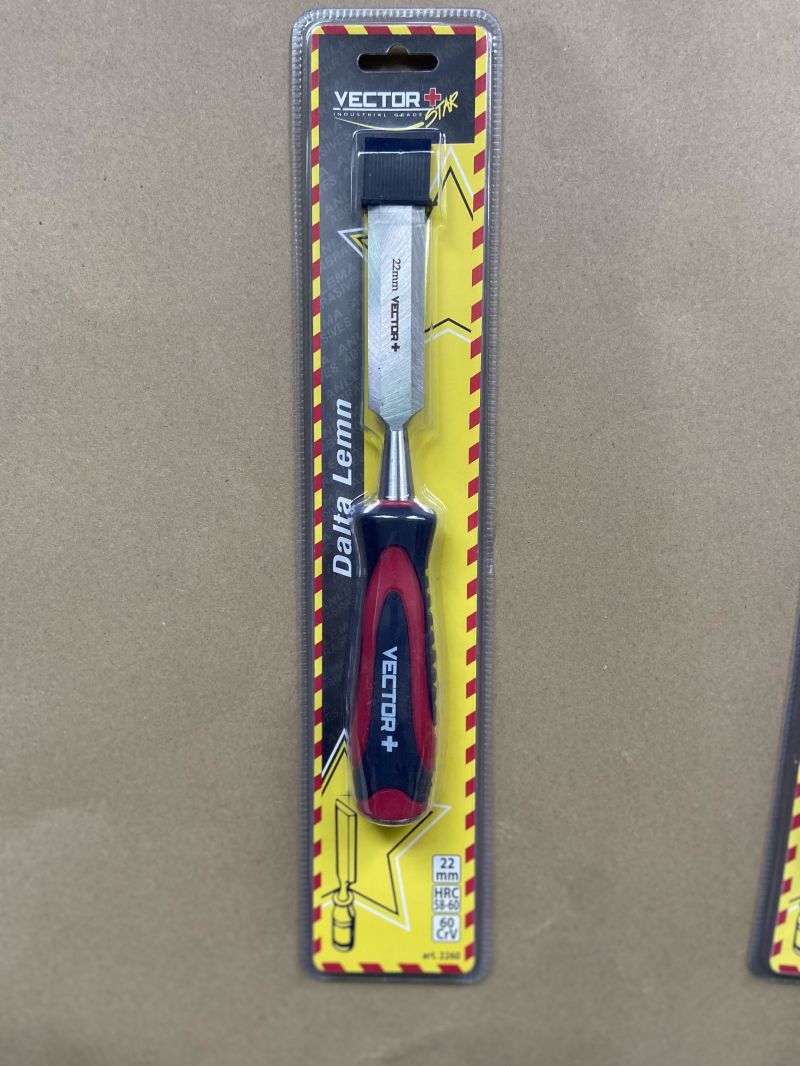

1. High-carbon hlau: High-carbon steel yog cov khoom siv rau cov ntoo chisels, muab lub zog zoo thiab ua haujlwm ntev.Nws yog tsim rau ntau hom ntoo, tshwj xeeb tshaj yog hardwoods thiab high-density ntoo.

2. Kev kub ceev steel: High-speed steel yog ib yam khoom uas zoo heev hardness thiab kub stability.Nws feem ntau yog siv los tuav cov ntoo nyuaj lossis cov xwm txheej uas xav tau kev txiav ceev.

3.Tungsten alloy: Tungsten alloy yog cov khoom siv zoo heev thiab hnav-tiv taus siv hauv kev tsim cov ntoo chisels zoo.Nws yog tsim rau kev ua hauj lwm nrog hardwood, plywood, thiab composite cov ntaub ntawv.

Lub hardnessntawm ib tug ntoo chisel nyob ntawm cov khoom nws yog tsim los ntawm.Ntoo chisels feem ntau yog ua los ntawm high-carbon steel, high-ceev steel, los yog tungsten alloy, uas muaj sib txawv hardness theem.Nov yog qee qhov kwv yees hardness ranges rau cov ntaub ntawv no:

1. High-carbon steel: High-carbon steel siv rau ntoo chisels feem ntau muaj ib tug hardness li ntawm 55 mus rau 62 HRC (Rockwell Hardness Scale).Qib ntawm hardness no tso cai rau lub chisel kom muaj lub ntsej muag ntse thiab tiv taus hnav thaum siv.

2. High-speed steel: High-speed steel siv rau ntoo chisels paub txog nws tshwj xeeb hardness.Nws feem ntau muaj qhov nyuaj ntawm 62 txog 67 HRC, muab cov ntug tuav thiab tiv thaiv kom sov thiab hnav.

3. Tungsten alloy: Tungsten alloy chisels yog ib qho nyuaj thiab ruaj khov.Lawv feem ntau muaj qhov nyuaj ntawm 65 txog 70 HRC lossis siab dua.Lub siab hardness ntawm tungsten alloy ua kom zoo heev txiav kev ua tau zoo thiab txuas ntxiv lub neej.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov nyuaj ntawm cov ntoo chisel yuav txawv nyob ntawm seb hom hom twg, kev tsim khoom, thiab kev kho cua sov siv rau lub cuab yeej.Nco ntsoov xa mus rau cov chaw tsim khoom cov lus qhia tshwj xeeb lossis sab laj cov ntaub ntawv khoom los txiav txim siab qhov nyuaj ntawm ib qho ntoo chisel.

Kev siv txuj ci:

1. Ceev ceev: ntse yog qhov tseem ceeb rau kev txiav ntoo chisels.Tsis tu ncua tshuaj xyuas cov chisel hniav thiab siv lub pob zeb sharpening los yog grinder kom muaj kev ntse.

2. Tswj kev txiav quab yuam: Thaum siv ntoo chisels, siv lub zog txiav nruab nrab thiab tsis txhob siab dhau.Kev quab yuam ntau dhau tuaj yeem ua rau lub chisel tau daig lossis ua rau cov hniav puas.Siv maj mam thawb thiab twisting motion kom smoothly nce lub chisel hniav los ntawm cov ntoo.

3. Precise positioning: Ua ntej pib lub chiseling, kos lub qhov xav tau txiav qhov chaw uas siv ib tug pas ntsuas, mem hluav, los yog cov cuab yeej cim.Xyuas kom tseeb tias cov chisel hniav pib txiav los ntawm txoj hauj lwm kom raug rau qhov tseeb.

4. Xaiv cov chisel uas tsim nyog: Ntoo chisels tuaj nyob rau hauv ntau yam duab, xws li tiaj chisels, round chisels, thiab square chisels.Xaiv cov chisel zoo uas haum rau cov haujlwm tshwj xeeb kom tau txais txiaj ntsig zoo.

5. Siv lub mallet: Rau cov dej num uas yuav tsum tau muaj zog ntau dua, koj tuaj yeem siv cov ntoo mallet los pab cov chiseling.Maj mam kov tus kov ntawm lub chisel kom tsav cov hniav mus rau hauv cov ntoo, tab sis yuav tsum ceev faj kom tswj tau lub zog thiab tsis txhob hnyav hnyav hnyav uas yuav ua rau muaj kev puas tsuaj.

6.Kev ceev faj txog kev nyab xeeb: Ib txwm saib xyuas kev nyab xeeb thaum siv ntoo chisels.Xyuas kom cov ntoo ruaj ruaj kom tsis txhob ntog lossis raug mob.Tsis tas li ntawd, hnav cov khoom tiv thaiv tus kheej tsim nyog, xws li kev tiv thaiv qhov muag thiab hnab looj tes, txhawm rau tiv thaiv koj tus kheej thaum ua haujlwm.

Post lub sij hawm: Jun-09-2023