Kev xaiv thiab siv cov khoom siv thiab cov qauv ntawm cov milling cutter nyob ntawm cov khoom siv thiab kev ua haujlwm.

Hauv qab no yog qee cov qib milling cutter thiab xaiv cov lus qhia:

1.High-speed steel (HSS) milling cutter: haum rau kev ua qee cov ntaub ntawv nyuaj, xws li hlau, cam khwb cia hlau, stainless hlau, thiab lwm yam. Machining tuaj yeem ua tiav nrog qhuav (tsis muaj lubrication) lossis ntub dej txias.

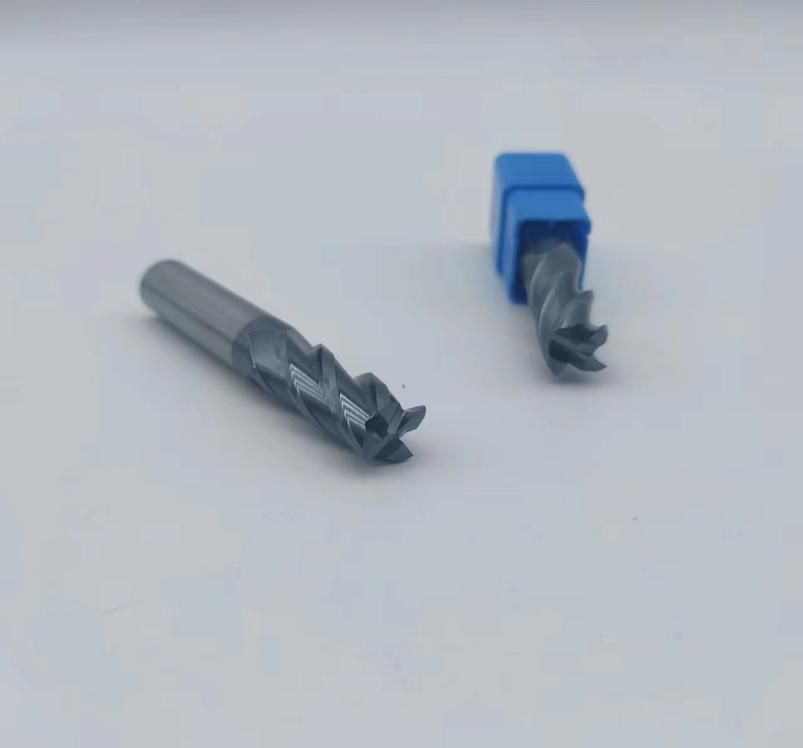

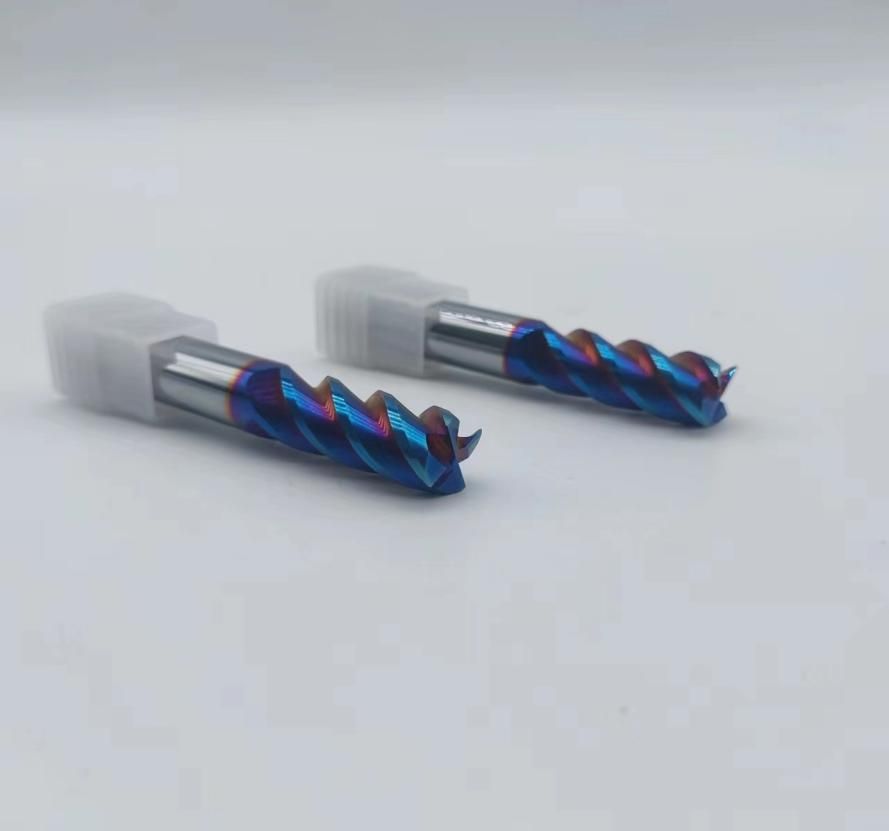

2.Tungsten carbide (WC) milling cutter: tsim nyog rau kev ua cov ntaub ntawv siab hardness, xws li titanium alloy, siab hardness alloy steel, thiab lwm yam. Vim nws cov hardness siab, nws yog pom zoo kom ntub dej txias.

3.PCD milling cutter (polycrystalline pob zeb diamond): tsim nyog rau kev ua cov ntaub ntawv nyuaj, xws li cov ntaub ntawv refractory, ceramics, iav, thiab lwm yam. Vim nws tsis zoo cua sov dissipation, nws yuav tsum tau siv nyob rau hauv ntub txias.Thaum xaiv hom milling cutter, nws yuav tsum tau txiav txim siab raws li qhov hardness, nto zoo thiab ua ntim ntawm cov khoom ua tiav.Feem ntau hais lus, ntau cov hniav ntawm cov milling cutter tuaj yeem siv los txhim kho qhov smoothness, thaum cov hniav tsawg dua tuaj yeem siv los ua kom nrawm nrawm, tab sis yuav tsum tau saib xyuas kom tsis txhob muaj cua sov ntau dhau thaum siv.Tsis tas li ntawd, kev siv cov milling cutters me me los yog loj dhau yuav tsum raug zam, kom tsis txhob ua rau muaj kev puas tsuaj rau cov milling cutters me me dhau lawm, thiab cov milling cutters loj dhau yuav ua rau cov khoom tsis sib xws thiab cov khoom siv pov tseg.

Lub neej kev pab cuam ntawm lub tshuab milling yog nyob ntawm ntau yam, xws li cov khoom, geometry, cov khoom siv, txiav quab yuam, txiav ceev thiab txias txoj kev ntawm lub tshuab txiav.Feem ntau hais lus, milling cutters yuav muaj kev hnav thiab qaug zog thaum lub sijhawm ua haujlwm, ua rau lawv poob lawv qhov ntse thiab raug, ua rau txo cov khoom zoo thiab txo kev ua haujlwm.

Yuav kom ncua lub neej kev pab cuam ntawm lub milling cutter, cov nram qab no yuav tsum tau them sai sai rau:

1.Xaiv qhov tsim nyog milling cutter cov ntaub ntawv thiab geometry, thiab xaiv raws li qhov hardness, txiav ceev thiab cuab tam lub neej yuav tsum tau ntawm cov khoom ua tiav.

2.Reasonably teem lub txheej txheem tsis, xws li txiav ceev, pub ceev thiab txiav qhov tob, thiab lwm yam., thiab tsis txhob siv ntau heev txiav ceev thiab pub ceev kom tsis txhob hnav ntau dhau.

3. Khaws cov milling cutters txias thiab lubricated, siv cov coolants thiab lubricants kom tsis txhob muaj cua sov thiab hnav.

4.Nyob huv thiab tshuaj xyuas cov milling cutters, zam tus cwj pwm phem ntawm accumulating chips thiab deposits, thiab tsis tu ncua soj ntsuam thiab hloov hnyav milling cutters.

5.Khoom thiab tiv thaiv milling cutters los ntawm txhua yam, tshuaj lom neeg los yog corrosive puas, xws li siv kev xyaum lub thawv los yog jigs, thiab tsis txhob raug cov pa phem los yog ncaj qha tshav ntuj.

Post lub sij hawm: Mar-13-2023